In international badminton racket sourcing, more B2B buyers are realizing that long-term cooperation depends not on price alone, but on the factory’s overall capabilities. Choosing a reliable badminton racket factory is the first step for brands and wholesalers to manage risk.

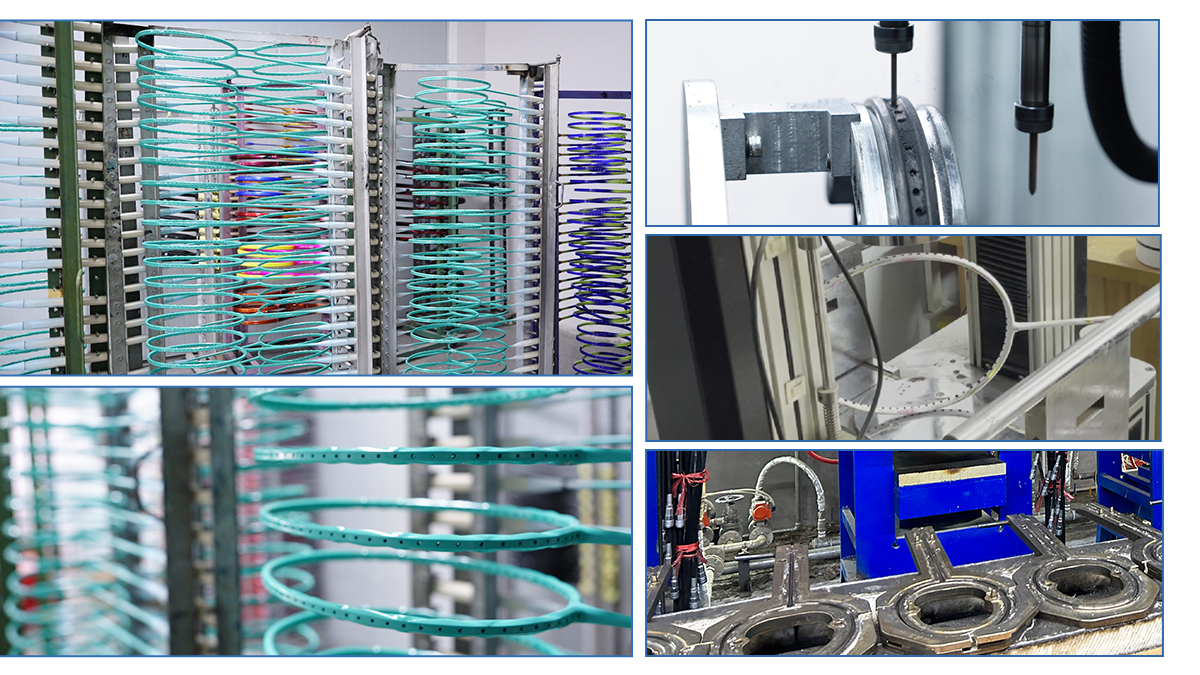

First is product consistency. Badminton rackets are high-frequency use sports products, and factors like carbon fiber layers, frame stability, and weight tolerance directly affect hitting feel. For overseas markets, consistency across batches is often more important than single-item specifications.

Second is manufacturing experience and category expertise. Factories with long-term badminton racket OEM/ODM experience are familiar with different market preferences—speed-oriented in Asia, durability-focused in Europe and the U.S. Such expertise cannot be replicated quickly.

Third is quality control system. From raw material selection to molding and final inspection, a stable QC process determines whether products can be exported reliably. B2B buyers often focus on a factory’s internal standards, not just sample performance.

Fourth is customization and collaboration ability. This includes appearance design, specification adjustments, and packaging solutions. Mature factories can flexibly support brand customization while maintaining consistent quality.

As a source factory with years of experience in sports equipment, Dmantis Sports focuses on stable production and long-term partnerships, providing reliable badminton racket OEM solutions for clients worldwide.

Copyright © Dmantis Sports Goods Co., Ltd. All Rights Reserved